Steel rolling system is a series of equipment and processes used in the production of various profiles, bars, wires, plates, strips and steel pipes in the process of metal processing. Rolling is the process of changing the shape and size of metal materials in a plastic state by applying external forces.

The main components of the rolling system include:

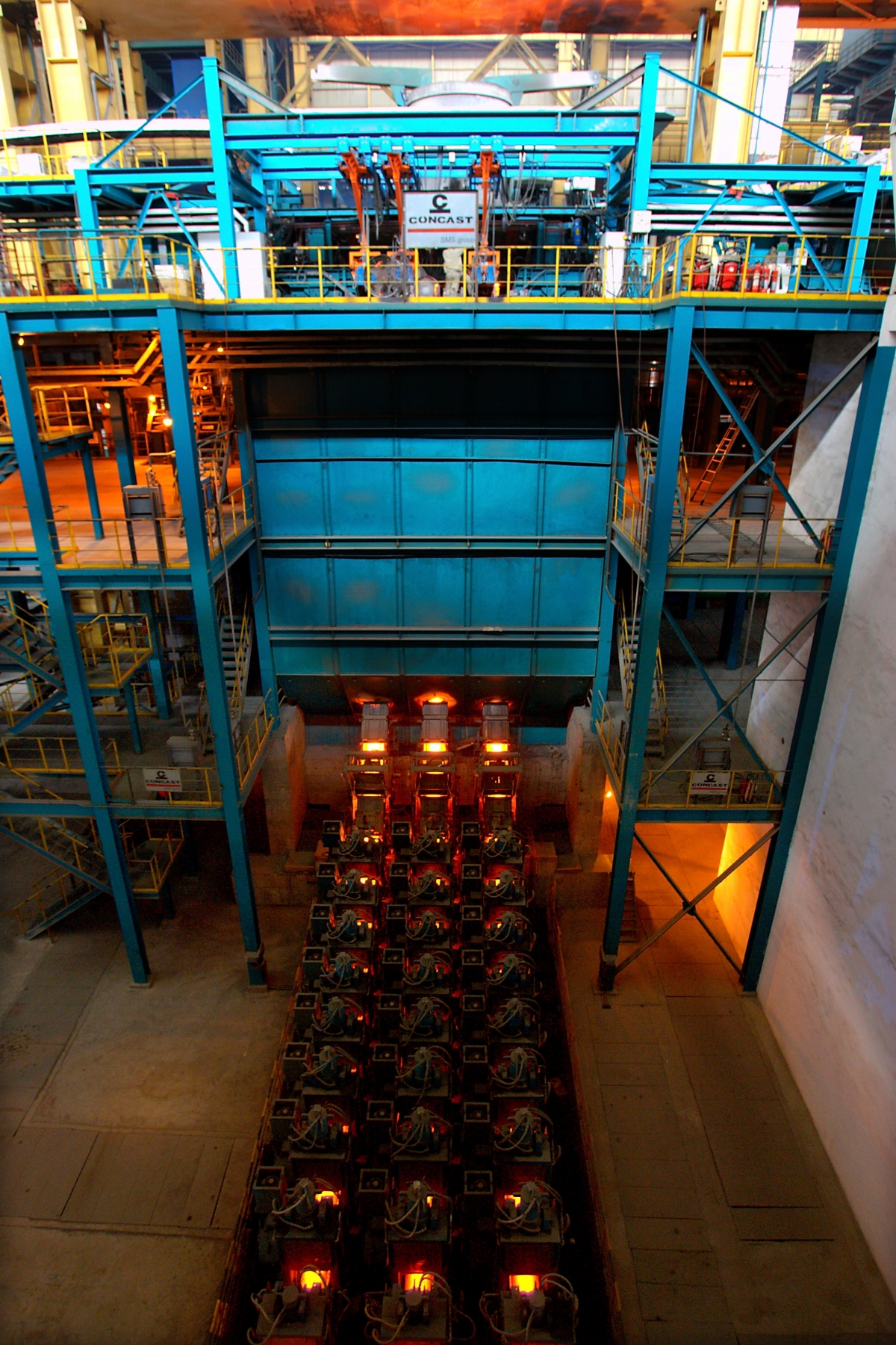

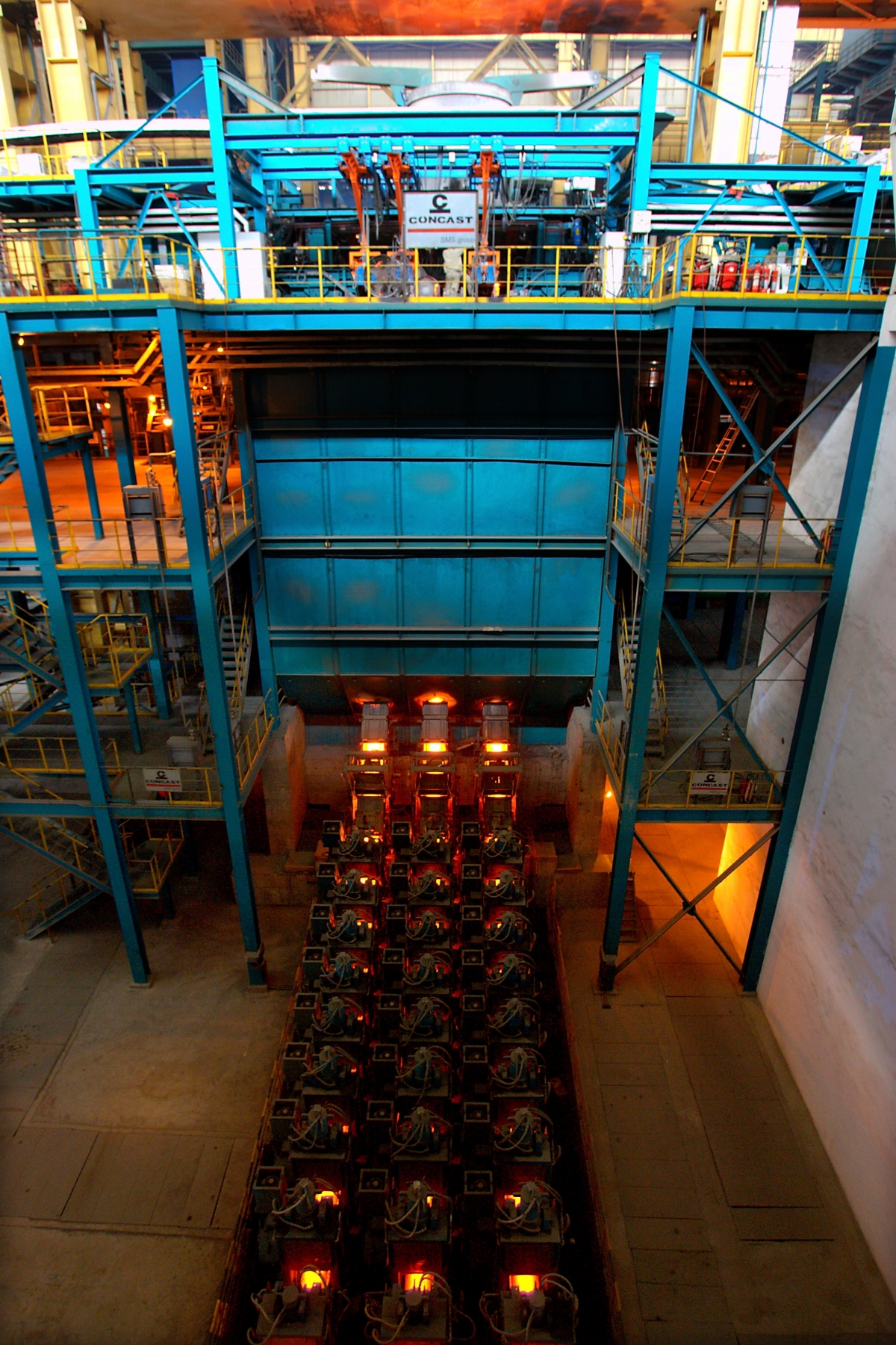

1. Preparation area: including heating furnace (such as walking furnace, continuous furnace), used to heat the metal billet to the temperature suitable for rolling.

2. Roughing zone: The roughing mill (such as billet breaking machine, roll diameter of the mill) is used for preliminary deformation of the billet, reducing the section and increasing the length.

3. Finishing zone: The finishing mill (a mill with a smaller roll diameter) is used to precisely roll the material to the desired size and shape.

4. Straightener: used to eliminate bending and distortion during the rolling process to ensure the straightness of the product.

5. Cooling device: the rolled metal needs to be cooled to reduce the temperature and prevent deformation and cracking, and the commonly used cooling methods are water cooling and air cooling.

6. Cutting equipment: used to cut continuously rolled strips into the required length of the product.

7. Inspection and packaging: Finally, the size, shape and performance of the product are inspected, and the product is packaged and ready for delivery.