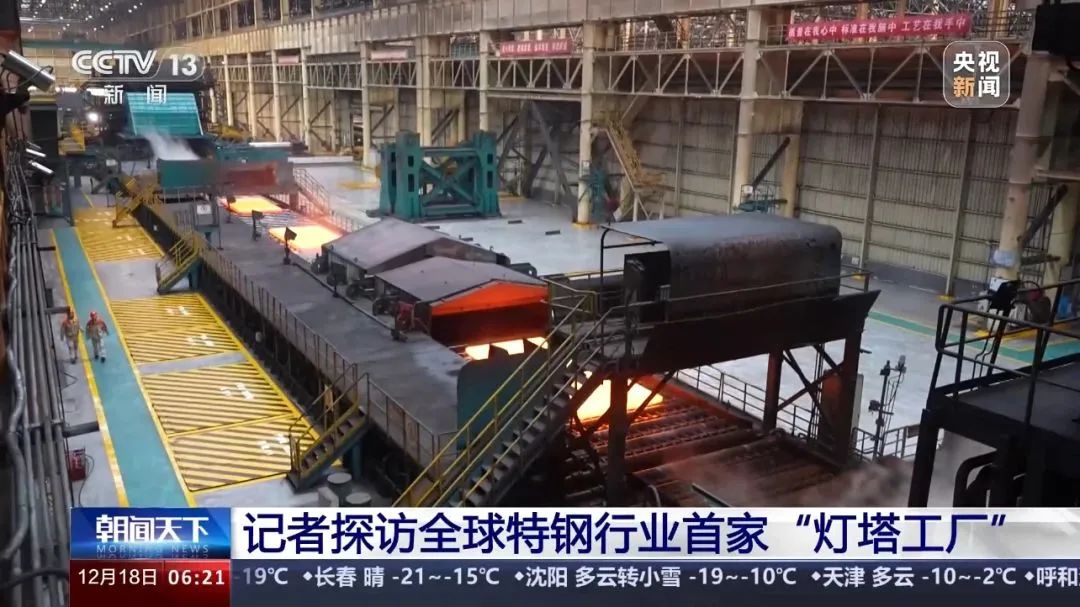

On January 25, Xingcheng Special Steel, a subsidiary of CITIC Pacific Special Steel, once again appeared on CCTV's "Focus Interview" as the new "identity" of "Lighthouse factory".

Large model is a new engine to drive industrial intelligence, and manufacturing is the most important field for artificial intelligence to accelerate the formation of new quality productivity. Located in Jiangyin, Jiangsu Province, the first "lighthouse factory" in the global special steel industry is known as the world's most advanced factory, representing the top intelligent manufacturing capabilities in the industrial field. An important reason why this company was rated as a "lighthouse factory" last year is that they adopted a large number of artificial intelligence technologies such as large models in the digital intelligent transformation, which greatly improved the level of intelligence and production efficiency.

Wang Xiaomin, intelligent director of Xingcheng Special Steel Plate branch of Citic Pacific Special Steel Group: "There are thousands of high-precision testing instruments all over the site, which is equivalent to our five senses, and can obtain the status of the production line in real time, on this basis, an intelligent model based on industrial mechanism and AI is established, and the optimal guidance strategy is obtained through the continuous self-learning of the model to guide the production." At present, our labor productivity has increased by 29.8%, and quality loss costs have decreased by 46.7%."

This "lighthouse factory" can produce 6.9 million tons of special steel per year. Through the combination of artificial intelligence technology and high-precision induction instruments, they solve the contradiction between multi-variety, small batch and large-scale production in the special steel industry, and can realize the flexible customization of products. At present, the number of customized orders has increased by 35.3%.

Wang Xiaomin: "Enterprises use a large number of industrial Internet technology to collect real-time field data to the cloud platform, and deploy artificial intelligence models on the cloud platform. Use this massive amount of data to train more powerful and accurate models for complex and varied production tasks."